Controlling algae growth in and nitrates in aquariums can be a challenging task, regardless of whether you own a freshwater, salty or marine aquatic tank.

These unwanted guests seem to appear out of nowhere, but they actually rely on nourishment just like plants do.

However, maintaining low levels of nitrate is crucial for keeping an algae-free tank. In this blog, we will discuss how to bring down nitrate levels in fish tank, and how to reduce nitrate in reef tanks along with some best nitrate test kits!

What is an Aquarium Nitrate?

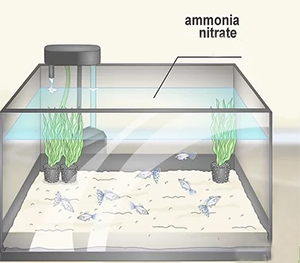

Nitrate is a natural byproduct that occurs when nitrite undergoes conversion during the later stages of the nitrogen cycle in an aquarium.

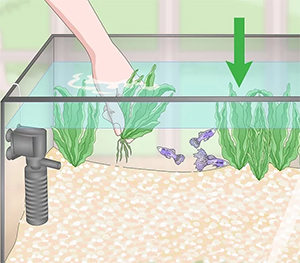

This process happens regularly and can be found in different amounts in almost all types of aquariums. It is caused by various factors such as decaying organic matter, leftover plant materials, clogged filters, overfeeding, or having too many inhabitants in the tank.

Nitrate is a nutrient for plants in your aquarium. However, if nitrates in fish tank builds up too much, it might encourage unfavorable algae growth. So it is essential to keep a close eye on nitrates in fish tank to maintain a healthy aquatic environment.

Disclosure: This article contains affiliate links. When you follow a link to purchase the products, I sometime earn a commission, at no additional cost to you. Read my full disclosure here.

How to Measure Nitrates in Fish Tank?

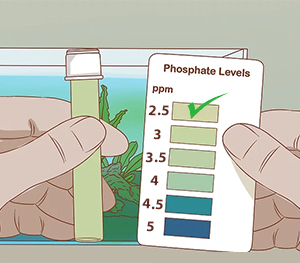

Aquarists count on water test strips or kits to determine the nitrates in fish tank. In less than a minute, these strips rapidly measure nitrates and other variables.

You can determine the nitrates in fish tank by placing the strip into the aquarium, gently swirling it underwater, and waiting a minute. Then, you can compare the colors of the strip to a provided chart.

What is the Ideal Level of Nitrate Fish Tank?

Nitrate is less toxic than ammonia and nitrite, which may cause damage to animals even in tiny amounts.

However, there is little information on how nitrates in fish tank affects various aquarium animals. For instance, guppy fry was fine in a study up to 800 ppm nitrate. Nitrate levels should be kept between 80 and 100 ppm.

Moreover, nitrates in fish tank affect plants as their leaves may turn yellow and disappear in its absence (0–20 ppm). So, to ensure that plants in tanks grow well, a target nitrate level of 50 ppm is set.

What Causes Increase in Nitrates in Aquariums?

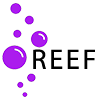

- Overfeeding: An excessive amount of nitrates in fish tank often stems from overfeeding. When we provide our fish with more food than they can consume, it results in an excess of waste.

Additionally, any uneaten food that remains decays and further contributes to water pollution. Similarly, overcrowding the tank with too many fish also leads to increased nitrates in fish tank. A larger number of fish means a greater accumulation of waste.

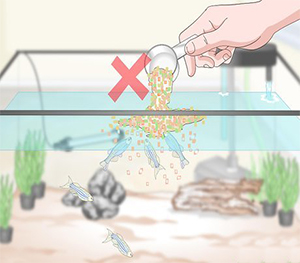

- Overstocking: It is not uncommon to unintentionally end up with an excess number of fish. Overcrowding the tank with too many fish also leads to increased nitrates in fish tank. A larger number of fish means a greater accumulation of waste.

Opting for fewer fish is preferable but if your tank becomes crowded, you may need to either reduce the population or invest in a larger tank size.

- Dirty Filters: Maintaining clean filters is essential in preventing elevated nitrate levels in your aquarium. Over time, filters accumulate waste, food scraps, and debris that contribute to these high nitrate levels. Regularly cleaning or replacing the filter helps prevent this buildup from lingering and affecting water quality.

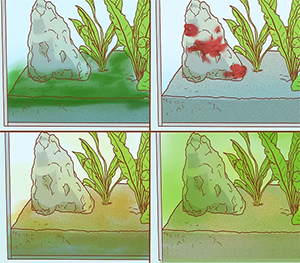

- Decayed Plant: While aquarium plants are beneficial for reducing nitrates in fish tank, their dead leaves can cause issues if not removed promptly.

When these leaves are ignored, the decaying leaves further break down and contribute to additional waste production.

Problems with High Level of Nitrates in Fish Tank

- Algae Overgrowth: When nitrates in fish tank become too high, it can result in an overgrowth of algae known as “algal bloom.” This imbalance can be detrimental to the tank’s appearance and the well-being of fish by causing green water and a decrease in oxygen levels.

- Fish Health Concerns: While ammonia and nitrite are more toxic to fish, high levels of nitrates in fish tank can also have negative effects.

Freshwater fish tend to be more tolerant of higher nitrate levels, but excessive amounts can still lead to signs of illness. Neglected tanks often experience a gradual buildup of nitrates, which can pose problems for new fish.

- Saltwater Tanks: Nitrates in fish tank are particularly important for saltwater tanks as saltwater fish are quite sensitive to them. It is crucial to maintain nitrate levels below 20 ppm (parts per million) in order to preserve the delicate balance within these tanks.

- Coral Reef Tanks: In coral reef tanks, it is important to maintain nitrates in fish tank at levels below 5 ppm. Nitrates can have negative effects on the health and vibrancy of corals by reducing oxygen levels and causing fading.

However, it is also necessary to ensure that corals receive some level of nitrates for their survival. So, make sure you balance nitrates in fish tank accordingly!

How to Bring Down Nitrite Levels in Fish Tank?

If your water has increase level of nitrites and you are seeking how to bring down nitrite levels in fish tank, read below;

- Reducing Nitrate Input: Preventing excessive nitrate levels is vital. Nitrate can enter tanks through multiple sources, such as replacement water, supplements, and fish food. Opt for purified water, ensure nitrate-free additives are used, and be mindful of moderating the amount of fish food for how to bring down nitrite levels in fish tank.

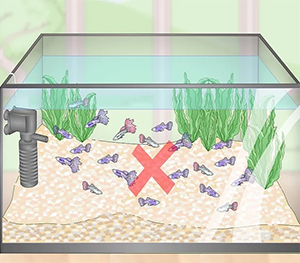

- Regular Water Changes: Regularly changing a portion of the water in your tank is an effective method for how to bring down nitrite levels in fish tank. By doing a 20% water change, for example, you can reduce nitrate by 20%. Additionally, consider using chemical filter media like the Deep Blue Professional’s nitrate reducer filter pad to address sudden spikes in nitrates.

- Setting up a Refugium: A planted refugium provides a convenient way for how to bring down nitrite levels in fish tank. Live macroalgae in the refugium can directly absorb nitrate from the water.

Regular removal of portions of the algae helps eliminate excess nitrate and other nutrients. While there is some initial setup involved, refugia offers an ongoing and natural method of reducing nitrate levels. - Utilizing Microbes: Microorganisms are considered as another best alternative for how to bring down nitrite levels in fish tank.

Certain microbes have the ability to store nitrate for their own growth, while others can convert it into other forms such as nitrogen gas. It is possible to obtain live cultures of these bacteria, including aerobic and anaerobic varieties.

Aerobic bacteria are efficient in quickly using up nitrate when provided with a carbon source, whereas anaerobic bacteria work at a slower pace and are commonly found in sediment, reducing the risk of oxygen depletion.

How to Reduce Nitrate in Reef Tank?

- Reduce Feeding: For how to reduce nitrate in reef tank, it is important to be mindful of the amount of food you feed to your fish. Overfeeding can lead to excessive nitrate production, even for experienced hobbyists who may unintentionally add too much food in a hurry.

- Type of Food: Additionally, the type of fish food you use can help you with how to reduce nitrate in reef tank. Some foods are more nutrient-packed and contribute more nitrates, such as pellet food. To balance nutrition and minimize nitrate buildup, consider introducing fish food variety by adding frozen foods alongside pellets.

- Improve Mechanical Filtration: Enhancing the efficiency of mechanical filters can help in capturing solid waste before it gets converted into nitrates. Regularly changing filter socks and cleaning the protein skimmer can significantly boost their performance. Additionally, exploring options such as automatic filter rollers or sediment filters in a BRS Reactor can further enhance mechanical filtration.

- Implement Natural Nitrate Reduction Methods: Considering natural methods like using refugium with macroalgae, chaeto-reactors, or turf scrubbers for how to reduce nitrate in reef tank. These techniques involve the growth of algae to absorb excess nitrates from the water. Furthermore, harvested algae serves as an effective means to export nitrates out of the aquarium system.

- Carbon Dosing & BioPellets: For more complex situations, experienced aquarists have the option to consider carbon dosing or biopellet utilization. These techniques involve introducing carbon sources to stimulate bacterial growth and facilitate how to reduce nitrate in reef tank.

It is important to note that these methods require a certain level of expertise as they can influence the tank’s bacterial equilibrium.

Best Nitrate Test Kits

Now, that you have gone through how to reduce nitrate in reef tank and how to bring down nitrate levels in fish tank, we’re going to present you with 3 best nitrate test kits.

Have a look!

1. Salifert Nitrate (No3) Test Kit

Quick view on Amazon

Available in: Australia, Canada, UK and US

It’s crucial to be aware that many nitrate test kits can get influenced by amine, which could result in falsely low nitrate level readings. The Salifert test kit, which doesn’t experience these interference problems, offers a solution. This specific test kit stands out since it delivers precise results rapidly and can be used to conduct testing in under three minutes.

2. NYOS Nitrate Reefer Test Kit

Quick view on Amazon

Available in: Australia, Canada, UK and US

The NYOS REEFER test kits are a compelling alternative for aquarium enthusiasts looking for accurate measurements that match laboratory-level accuracy without costing too much. These kits were created by professionals to address the crucial necessity for preserving water characteristics that closely resemble natural circumstances, which is essential for the development of aquariums.

3. AQUA CARE PRO Freshwater Test Strips

Quick view on Amazon

Available in: Australia, Canada, UK and US

The Aqua Care Pro 6 in 1 freshwater aquarium test kit makes the testing procedure even more straightforward. This kit, developed by specialists in the field, provides a practical replacement for conventional liquid test kits. It not only accelerates the testing process but also makes it simpler for users to handle, dip into aquarium water, and precisely read the results thanks to its broader test strips and prominent colors.

Conclusion

We all know that nitrates are important for any aquarium but only to a certain extent. Anything that crosses its limit turns out to be more dangerous than any other thing, and thus, the same is the case with nitrates.

Therefore, always keep an eye on levels of nitrates because as said earlier, its high levels can

create multiple problems for your little aquatic residents!